Ceramic Band Heaters

- Product Info

- Techinical Specification

- Ordering Information

- Termination & Clamping Options

- Installation & Maintenance

Anupam's Ceramic Band Heaters were developed to meet industrial requirements for high temperature long lasting heaters. They are ideally suited to comply with today's new resins, which calls for ever-increasing process temperatures.

An additional advantage of the Ceramic Band Heaters is that they transfer heat through conduction and radiation. This makes their tightness on barrels less critical; thus they are less prone to thermal expansion problems.

Theoretically, there are no restrictions on the diameter that ceramic band heaters can attain; however, because these heaters utilize ceramic tiles that are available only in specific lengths, the width of these heaters falls within a certain incremental range of sizes.

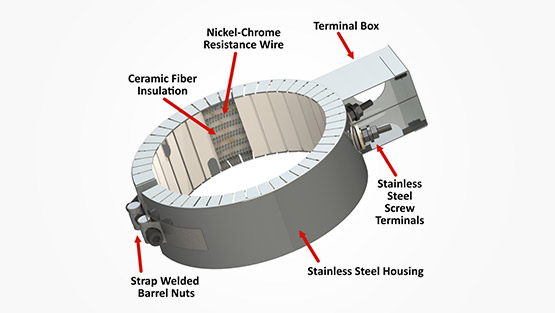

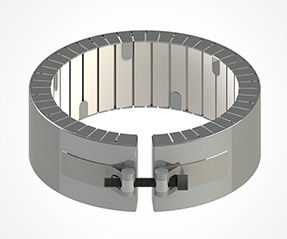

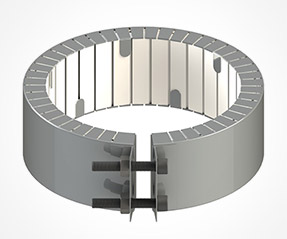

Construction

Ceramic band heaters are designed with spirally wound inner resistance coils evenly threaded through interlocking insulated ceramic “tiles”. The ceramic core, or “mat” of tiles is housed beneath a stainless steel sheet with serrated edges. This combined assembly of the Ceramic Band Heater offers a flexible heating system that yields efficient transmission of conduction and radiated heat. The heat of the Ceramic Band originates from the inner coils that conduct heat at maximum temperatures. The heated coils evenly deliver heat through the ceramic tiles which radiate energy to the barrel. We offer a variety of Ceramic Band styles with customized configurations.

Advantages

- Built in insulation minimizes unwanted change in temperature along the barrel

- Heat transfers through radiation, conduction, and convection, so a perfect fit is not required compared to other band heaters

- Heat transfers are not affected by irregular surfaces or a loose fit

- Because they operate at higher watt densities, they can be used in wider increments

- The number of bands used can be reduced with simplified wiring

- The heater is safer with the cooler external surface – over other band heaters

- The flexible design allows easy install and removal

Application

- Injection Molding Machine

- Blow Molding Machine

- Extrusion Line

| Resistance | +10% -5% | Overall Thickness | 15 mm |

| Wattage | +5% -10% | Minimum Dia. | 38 mm |

| Max. Watt Density | 8 watts / sq.cm | Minimum Width | 25 mm |

| Voltage | 220V AC to 480V AC | Width - Normal | Multiple of 15 + 6mm |

| Maximum Temp | 800 oC | Std. gap between edges | 5 to 10 mm |

Ordering Information

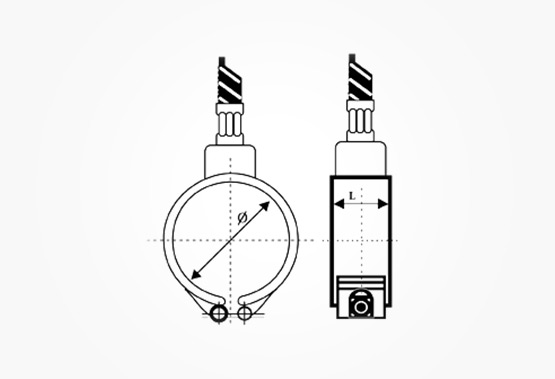

- Inside diameter (Ø)

- Length of the heater (L)

- Operating voltage (V)

- Wattage (W)

- Location dimensions of holes for T/C and slot in the heater (if any)

- Termination & Clamping Style

- Lead length

- Quantity

- In case of repeat order please specify Anupam code No. as punched on heater

Vertical Post Terminals

Post terminals provide optimum connections. Ceramic covers with openings for loads are screwed onto post terminals providing a convenient, economical insulator. Can be provided on heater length 40 mm or more.

Horizontal Post Terminals

Post terminals provide optimum connections. Ceramic covers with openings for loads are screwed onto post terminals providing a convenient, economical insulator. Can be provided on heater length 50 mm or more.

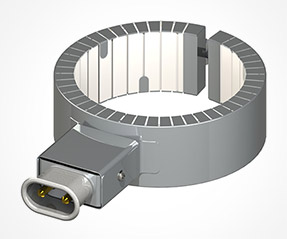

High Temperature Quick Disconnect Plug

This provides the simplest and fastest way to apply power to band heaters. This assembly eliminates all live exposed terminals and electrical wiring that can be potential hazard to employees or machine. Can be provided on heater length of 40mm or more. Recommended for heater capacity up to 2.5KW.

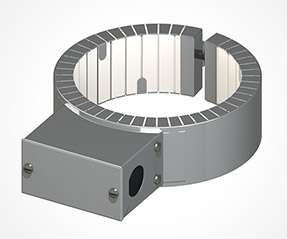

Metallic Terminal Box Connection

Metallic terminal boxes that attach directly to the heater act as a safety feature by covering the terminals. Can be provided on heater of length 40mm or more.

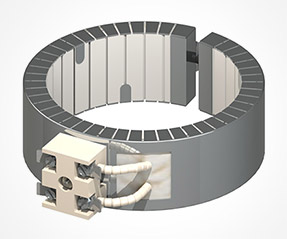

Ceramic Block Type Termination

Ceramic connector type terminal with metal protecting cover for easy wiring & wiring bunch. Easy to replace.

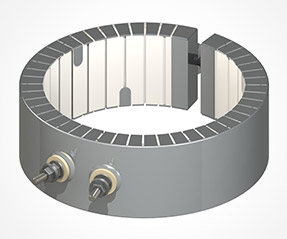

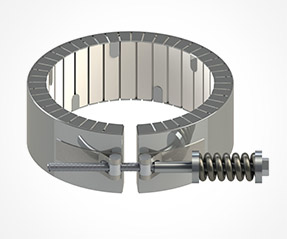

Spring Loaded Screw Clamp

Allen bolt with Spring Loaded Clamping systems provides excellent grip of the heater mounted vertically. Recommended in all Die heaters.

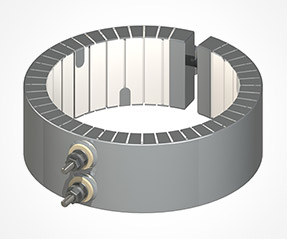

Standard Allen Bolt Clamp

Allen bolt with standard clamping system generally used on all heaters.

Flange Type Clamp

A Bent Outward Flange is an additional Clamping Option which can be used.

- Ceramic Band Heaters are very flexible and can be made in large widths and one-piece construction for easy installation eliminating heat losses between narrow bands and sharply reducing labor cost in installation

- Before installation & during operation, the surface of the barrel and ceramic band heater must be clean and free from all contaminants that might liquefy under heat and find there way into the heater elements, carbonizing and becoming conductive. The smallest amount of contamination can cause electrical shorts creating heater failure

- Tighten the Allen bolt until the serrated edges become firmly in direct contact with the barrel to get the uniform contact. Do not over tighten, as to the point where serrated edges begin to collapse and thrust outwards. Unlike all other types of band heaters, Ceramic heater works on conduction and radiation principle and they do not require the same clamping force essential on all other types of band heaters

- To prevent the overheating and heater failure, adequate temperature controllers should be installed. Thermocouples must be kept free of contaminants and checked for good response to temperature changes. A bad thermocouple can be the cause of destroying an entire heating Zone

- Keep all electrical connections properly protected to avoid accident

- Never perform any type of service on heaters without disconnecting all electrical power

- Incorrect wiring is a common cause in heater burn out

- Qualified person should do the electrical wiring of heaters