Energy Saving Band Heaters

- Product Info

- Techinical Specification

- Termination & Clamping Options

- Installation & Maintenance

Anupam's Unique Energy Saving Ceramic Band Heaters are Specifically designed and engineered to meet the ever increasing demand for energy conservation and to improve operation efficiency capable of generating higher temperature essential to process today's high temperature resins.

Energy Conservation is achieved by using 1" thick Ceramic fiber insulating blanket on the outer surface increasing the overall outer diameter by 2"(Minimum Length Required is 4"). Reducing power consumption upto 30% because of low thermal conductivity of the ceramic fiber insulation, the external surface temperature of the insulation plus ceramic band heater is approximately 80°C while running the inside surface temperature at 300°C

Features

- Saving Energy Up to 30%

- Reduce Wattage of Heater

- More Uniform Heating

- Less Down time increases Productivity

- Reduced Preheating time of Machine

- Heater cost is recover in shorter time

- Cool working atmosphere for operator

- Overall Outer diameter increases by 2" (50 mm)

Application

- Injection Molding Machine

- Blow Molding Machine

- Extrusion Line

| Resistance | +10% -5% | Overall Thickness | 40 mm |

| Wattage | +5% -10% | Minimum Dia. | 90 mm |

| Max. Watt Density | 8 watts / sq.cm | Minimum Width | 100 mm |

| Voltage | 220V AC to 480V AC | Width - Normal | Multiple of 15 + 6mm |

| Maximum Temp | 800 oC | Std. gap between edges | 5 to 10 mm |

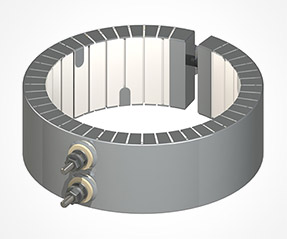

Vertical Post Terminals

Post terminals provide optimum connections. Ceramic covers with openings for loads are screwed onto post terminals providing a convenient, economical insulator. Can be provided on heater length 40 mm or more.

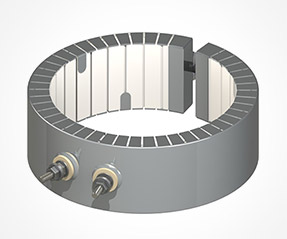

Horizontal Post Terminals

Post terminals provide optimum connections. Ceramic covers with openings for loads are screwed onto post terminals providing a convenient, economical insulator. Can be provided on heater length 50 mm or more.

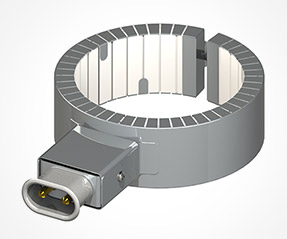

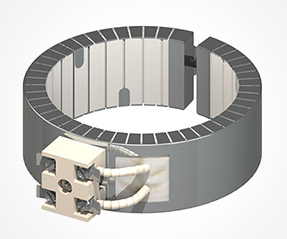

High Temperature Quick Disconnect Plug

This provides the simplest and fastest way to apply power to band heaters. This assembly eliminates all live exposed terminals and electrical wiring that can be potential hazard to employees or machine. Can be provided on heater length of 40mm or more. Recommended for heater capacity up to 2.5KW.

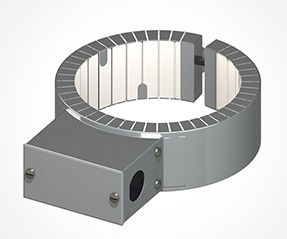

Metallic Terminal Box Connection

Metallic terminal boxes that attach directly to the heater act as a safety feature by covering the terminals. Can be provided on heater of length 40mm or more.

Ceramic Block Type Termination

Ceramic connector type terminal with metal protecting cover for easy wiring & wiring bunch. Easy to replace.

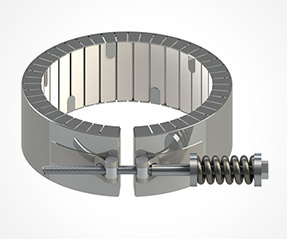

Spring Loaded Screw Clamp

Allen bolt with Spring Loaded Clamping systems provides excellent grip of the heater mounted vertically. Recommended in all Die heaters.

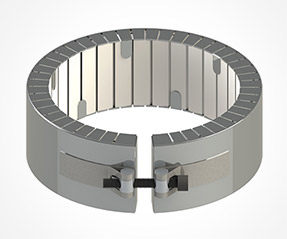

Standard Allen Bolt Clamp

Allen bolt with standard clamping system generally used on all heaters.

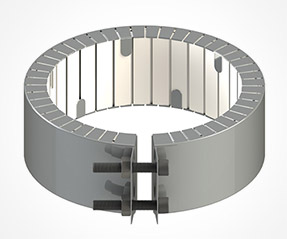

Flange Type Clamp

A Bent Outward Flange is an additional Clamping Option which can be used.

- Ceramic Band Heaters are very flexible and can be made in large widths and one-piece construction for easy installation eliminating heat losses between narrow bands and sharply reducing labor cost in installation

- Before installation & during operation, the surface of the barrel and ceramic band heater must be clean and free from all contaminants that might liquefy under heat and find there way into the heater elements, carbonizing and becoming conductive. The smallest amount of contamination can cause electrical shorts creating heater failure

- Tighten the Allen bolt until the serrated edges become firmly in direct contact with the barrel to get the uniform contact. Do not over tighten, as to the point where serrated edges begin to collapse and thrust outwards. Unlike all other types of band heaters, Ceramic heater works on conduction and radiation principle and they do not require the same clamping force essential on all other types of band heaters

- To prevent the overheating and heater failure, adequate temperature controllers should be installed. Thermocouples must be kept free of contaminants and checked for good response to temperature changes. A bad thermocouple can be the cause of destroying an entire heating Zone

- Keep all electrical connections properly protected to avoid accident

- Never perform any type of service on heaters without disconnecting all electrical power

- Incorrect wiring is a common cause in heater burn out

- Qualified person should do the electrical wiring of heaters