- info@anupamheaters.com

- +91-9819030025

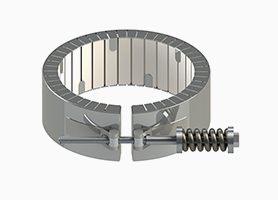

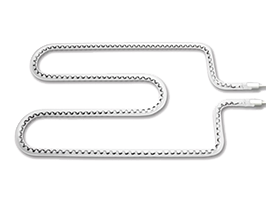

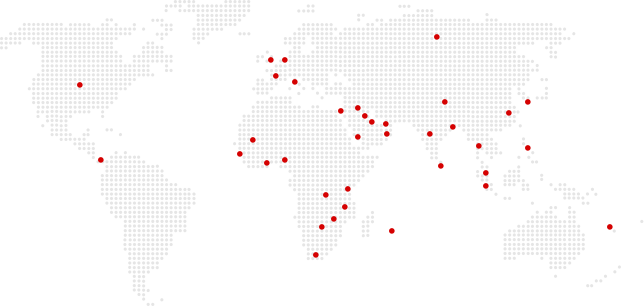

Established in 1984 & Pioneers in developing Ceramic Band Heaters in India, Today Anupam Heaters is one of the leading Indian companies to manufacture wide range of quality Heating elements for Plastic & Other Allied Industries. Since our inception, we have established a strong foothold in the Indian & Overseas market.

With sound technical expertise, large resource pool & experience gained for over more than two and half decades our company continues to maintain & exceed standards in terms of quality, customer satisfaction and timely delivery that are demanded by the best of companies across the globe. A team of technically sound & dedicated engineers along with best in class modern infrastructure and qualitative inputs, Anupam Heaters is poised to perform an increasingly important role in polymer and plastic manufacturing sector.

All information in Anupam Heaters ("ANUPAM") Catalog & Website was considered accurate and correct at the time of printing & publishing. ANUPAM has the right to make changes to specifications, designs and the Sales Terms and Conditions without prior notice. ANUPAM is not responsible for any typographical errors.