Energy Saving Insulation Jackets for Band Heaters

- Product Info

- Ordering Information

Energy Saving Insulation Jackets can be used on any brand of Injection Molding Machine. Their primary use lies in Saving Money by insulating the barrel from the Heat Loss. This in turn requires the Heater Bands to cycle less and lower electricity consumption.

By using these Insulation Jackets, you establish a thermal barrier that impedes temperature dissipation released to its surrounding which permits us to keep the heat generated where it should be, inside the barrel of the machinery.

Insulating Material - High Density Ceramic Fiber Wool, resistant to high temperature while maintaining its original state, durability and flexibility throughout its useful life. Resists temperature up to 1250 degree C.

Features

- Energy Saving of up to 35-40%

- Lowers Ambient Temperatures

- Non - Flammable Reusable Covers

- Multilayer Design to withstand High Temperatures

- Increases Heater Band Life

- Increases safety when working on or around the machines

- Velcro Closure system ensures best fitment

- Short payoff period

- Maximum personal protection

- Custom made for Easy Maintenance & Installation

- Corrosion Resistant & 100% Asbestos Free

Application

- Injection Molding Machine

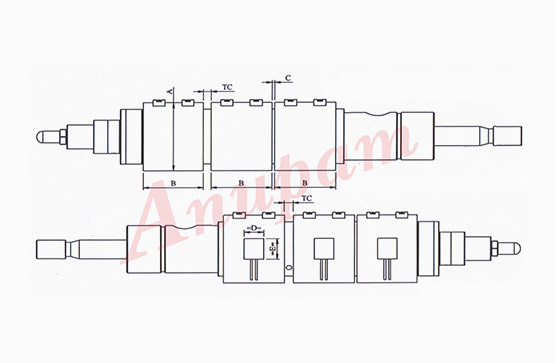

Send the Barrel Diagram with Heater as shown below with necessary dimensions.

- AOuter Diameter of the Heater

- BLength of the Heater

- CGap between the Heater Bands

- DWidth of the Terminal Box

- ELength of the Terminal Box

- TCGap between the Heater Bands (Where Thermocouple is mounted)