High Density Cartridge Heaters

- Product Info

- Applications

- Ordering Information

- Technical Specification

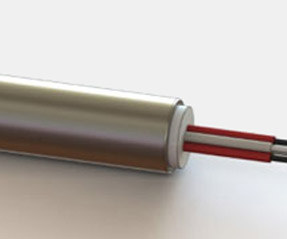

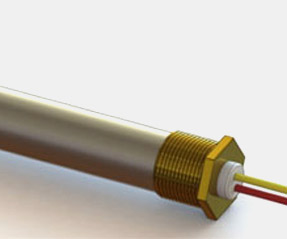

Anupam Heaters High Density Cartridge Heater can be considered "Component Heaters" that are used to heat up many different applications. Primarily used in moulds, dies & sealing bars, this Cartridge Heating Element fit snug inside a cavity and helps heat solids by reaching high temperatures. High Density Cartridge Heater has the versatility of being able to carry thermocouple inside to help control temperatures of the heater more accurately. Various diameters allow for the Cartridge Heating Element to be used in any cavity and can be custom designed with any cold section. Lead wires extend from the end to your controls.

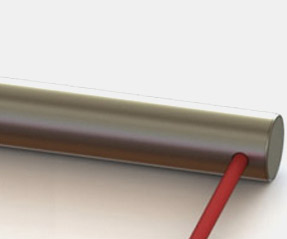

High Density Cartridge Heater distinguishes itself by its high compression and therefore especially efficient heat emission. That's why such Cartridge Heating Element is produced with a ground surface for a H7 fit.

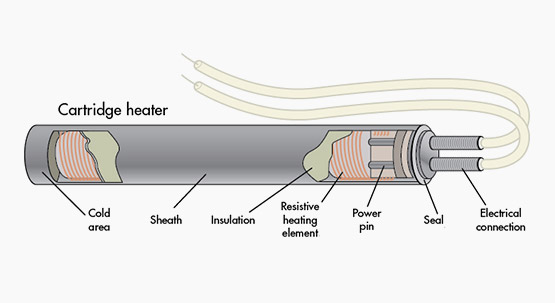

Construction

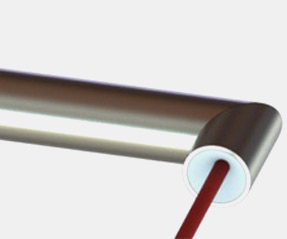

The construction of High Density Cartridge Heater positions a nickel-chrome resistance wire precision wound around a magnesium oxide core. It is inserted into a Stainless or Incoloy tube locating the resistance wire close to the sheath. The core is centrally positioned within the tube and filled with magnesium oxide powder. Nickel pins pass through the centre of the core making contact with the resistance wire at both ends. The whole assembly is highly compacted by a swaging operation and thus ensuring excellent heat transfer to the external sheath. One end of the heater is closed with a welded metal end-disc and wire leads exit at the opposite end which is typically closed with a lava seal. A variety of wire leads and lead protection options are available. The Cartridge Heating Element can be supplied with internal thermocouples, mounting fittings and many other options.

- DIE PLATEN HEATING

- DIE CASTING INDUSTRY

- EXTRUSION LINE

- HOT MELT ADHESIVES

- PACKAGING INDUSTRY

- PAPER INDUSTRY - EMBOSSING ROLLERS

- PREFORM MOLDS

- RUBBER MOLDING INDUSTRY

- SEAL BARS

- SEMI CONDUCTOR INDUSTRY

- TEXTILE INDUSTRY - HEATING OF CUTTING KNIVES

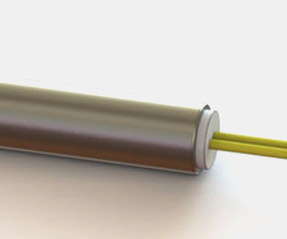

Inside Connection

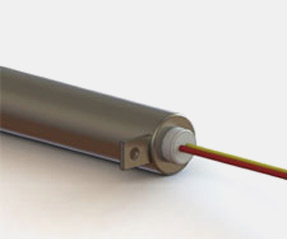

Outside Connection

Extended Cold Ends

Variable Wattage

With Ceramic Head

With Thermocouple

Fiberglass Sleeve

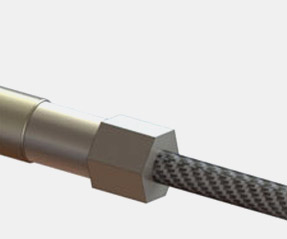

Metal Braided Sleeve

Flexible Metal Conduit

Termination Options

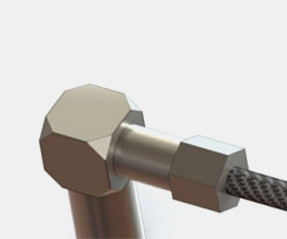

90° lead exit armour cable

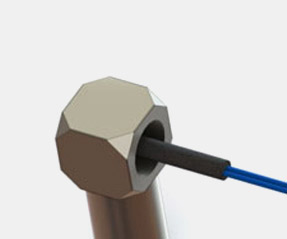

90° lead exit from sheath

90° lead exit stainless steel braid (SS)

90° lead exit with Stainless Steel Tube & Armour Cable

90° lead exit

90° Sheath Extension

Ceramic Beads

Inside Connection with Ceramic Head

Mounting Clip

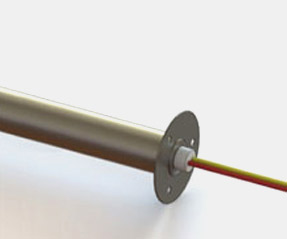

Mounting Flange

Silicone Sealed

Stainless Steel Braiding

Straight Armour Cable

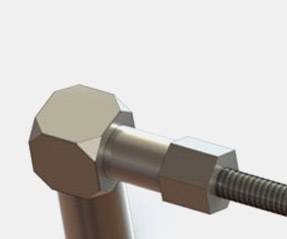

Threaded End Bottom

Threaded End Top

* The above 3D image are for pictorial representation only. Actual heater appearance may differ.

- 6.35mm

- 6.50mm

- 8.00mm

- 9.52mm

- 10.00mm

- 12.50mm

- 12.70mm

- 15.88mm

- 16.00mm

- 19.05mm

- 20.00mm

| Diameter | Length (MM) | Recommended Watts (W) | |||

| 6.35mm (-.02/.08mm) |

38 | 100 | 125 | 175 | 200 |

| 51 | 100 | 175 | 200 | 250 | |

| 64 | 125 | 200 | 250 | 300 | |

| 83 | 150 | 200 | 300 | 350 | |

| 102 | 200 | 300 | 400 | 450 | |

| 127 | 250 | 300 | 500 | 650 | |

| 152 | 300 | 400 | 650 | 800 | |

| Diameter | Length (MM) | Recommended Watts (W) | |||

| 6.50mm (-.02/.08mm) |

40 | 100 | 160 | 175 | 175 |

| 50 | 100 | 175 | 200 | 250 | |

| 60 | 125 | 200 | 250 | 300 | |

| 80 | 150 | 200 | 300 | 350 | |

| 100 | 200 | 300 | 400 | 450 | |

| 130 | 250 | 300 | 500 | 650 | |

| 160 | 300 | 400 | 650 | 800 | |

| Diameter | Length (MM) | Recommended Watts (W) | |||

| 8.00mm (-.02/.08mm) |

40 | 100 |

175 | 200 | 250 |

| 50 | 150 |

200 | 275 | 300 | |

| 60 | 100 |

175 | 300 | 350 | |

| 80 | 150 |

225 | 400 | ||

| 100 | 175 |

300 | 450 | ||

| 130 |

250 |

400 | 600 | ||

| 160 | 300 |

450 | 750 | ||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 9.52mm (-.02/.08mm) |

38 | 100 | 125 | 200 | 250 | 300 |

| 51 | 100 | 150 | 250 | 300 | 400 | |

| 64 | 125 | 175 | 300 | 400 | 500 | |

| 83 | 150 | 250 | 450 | 550 | 650 | |

| 102 | 225 | 350 | 550 | 700 | 850 | |

| 127 | 300 | 500 | 750 | |||

| 52 | 400 | 650 | 1000 | |||

| 178 | 450 | 700 | 1100 | |||

| 203 | 500 | 750 | 1200 | |||

| 254 | 650 | 1000 | 1500 | |||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 10.00mm (-.02/.08mm) |

40 | 100 | 125 | 200 | 250 | 300 |

| 50 | 100 | 150 | 250 | 300 | 400 | |

| 60 | 125 | 175 | 300 | 400 | 500 | |

| 80 | 150 | 250 | 450 | 550 | 650 | |

| 100 | 225 | 350 | 550 | 700 | 850 | |

| 130 | 300 | 500 | 750 | |||

| 160 | 400 | 650 | 1000 | |||

| 175 | 450 | 700 | 1100 | |||

| 200 | 500 | 750 | 1200 | |||

| 250 | 650 | 1000 | 1500 | |||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 12.50mm (-.02/.08mm) |

40 | 100 | 175 | 225 | ||

| 50 | 100 | 150 | 250 | 350 | 400 | |

| 60 | 200 | 350 | 500 | 650 | 800 | |

| 80 | 200 | 350 | 500 | 650 | 800 | |

| 100 | 250 | 400 | 650 | 800 | ||

| 130 | 400 | 650 | 1000 | 1250 | ||

| 160 | 500 | 800 | 1250 | |||

| 175 | 550 | 900 | 1250 | |||

| 200 | 800 | 1000 | 1500 | |||

| 250 | 1000 | 1500 | 1800 | |||

| 300 | 1000 | 1750 | 2000 | |||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 12.70mm (-.02/.08mm) |

38 | 100 | 175 | 225 | ||

| 51 | 100 | 150 | 250 | 350 | 400 | |

| 64 | 200 | 350 | 500 | 650 | 800 | |

| 83 | 200 | 350 | 500 | 650 | 800 | |

| 102 | 250 | 400 | 650 | 800 | ||

| 127 | 400 | 650 | 1000 | 1250 | ||

| 152 | 500 | 800 | 1250 | |||

| 178 | 550 | 900 | 1250 | |||

| 203 | 800 | 1000 | 1500 | |||

| 254 | 1000 | 1500 | 1800 | |||

| 305 | 1000 | 1750 | 2000 | |||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 15.88mm (-.02/.08mm) |

38 | 150 | 175 | 275 | 350 | |

| 51 | 150 | 200 | 350 | 400 | 500 | |

| 64 | 200 | 300 | 450 | 550 | 650 | |

| 83 | 300 | 400 | 650 | 800 | 1000 | |

| 102 | 315 | 400 | 630 | 800 | 1000 | |

| 127 | 500 | 700 | 1100 | 1400 | 1800 | |

| 152 | 600 | 900 | 1600 | 1800 | ||

| 178 | 750 | 1000 | 1750 | |||

| 203 | 800 | 1250 | 2000 | |||

| 254 | 1000 | 1500 | 2500 | |||

| 305 | 1250 | 1800 | ||||

| 355 | 1500 | 2500 | ||||

| 405 | 1600 | 2000 | ||||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

16.00mm (-.02/.08mm) |

40 | 150 | 175 | 275 | 350 | |

| 50 | 150 | 200 | 350 | 400 | 500 | |

| 60 | 200 | 300 | 450 | 550 | 650 | |

| 80 | 300 | 400 | 650 | 800 | 1000 | |

| 100 | 315 | 400 | 630 | 800 | 1000 | |

| 130 | 500 | 700 | 1100 | 1400 | 1800 | |

| 160 | 600 | 900 | 1600 | 1800 | ||

| 175 | 750 | 1000 | 1750 | |||

| 200 | 800 | 1250 | 2000 | |||

| 250 | 1000 | 1500 | 2500 | |||

| 300 | 1250 | 1800 | ||||

| 350 | 1500 | 2500 | ||||

| 400 | 1600 | 2000 | ||||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 19.05mm (-.02/.08mm) |

76 | 350 | 500 | 800 | 1000 | 1250 |

| 102 | 450 | 650 | 1000 | 1400 | 1600 | |

| 127 | 650 | 900 | 1400 | 1800 | 2200 | |

| 152 | 800 | 1100 | 1800 | 2200 | ||

| 178 | 900 | 1200 | 2000 | |||

| 203 | 1000 | 1500 | 2000 | |||

| 254 | 1600 | 2000 | ||||

| 305 | 1600 | 2000 | ||||

| 355 | 1750 | 2500 | ||||

| 406 | 2000 | 3000 | ||||

| 457 | 2500 | 3500 | ||||

| 508 | 2500 | 3500 | ||||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 20.00mm (-.02/.08mm) |

80 | 350 | 500 | 800 | 1000 | 1250 |

| 100 | 450 | 650 | 1000 | 1400 | 1600 | |

| 130 | 650 | 900 | 1400 | 1800 | 2200 | |

| 160 | 800 | 1100 | 1800 | 2200 | ||

| 175 | 900 | 1200 | 2000 | |||

| 200 | 1000 | 1500 | 2000 | |||

| 250 | 1600 | 2000 | ||||

| 300 | 1600 | 2000 | ||||

| 350 | 1750 | 2500 | ||||

| 400 | 2000 | 3000 | ||||

| 450 | 2500 | 3500 | ||||

| 500 | 2500 | 3500 | ||||

- 1/4 inch

- 3/8 inch

- 1/2 inch

- 5/8 inch

- 3/4 inch

| Diameter | Length (inch) | Recommended Watts (W) | |||

| 1/4” (-.02/.08mm) |

1.5 | 100 | 125 | 175 | 200 |

| 2.0 | 100 | 175 | 200 | 250 | |

| 2.5 | 125 | 200 | 250 | 300 | |

| 3.25 | 150 | 200 | 300 | 350 | |

| 4.0 | 200 | 300 | 400 | 450 | |

| 5.0 | 250 | 300 | 500 | 650 | |

| 6.0 | 300 | 400 | 650 | 800 | |

| Diameter | Length (inch) | Recommended Watts (W) | ||||

| 3/8" (-.02/.08mm) |

1.5 | 100 | 125 | 200 | 250 | 300 |

| 2 | 100 | 150 | 250 | 300 | 400 | |

| 2.5 | 125 | 175 | 300 | 400 | 500 | |

| 3.25 | 150 | 250 | 450 | 550 | 650 | |

| 4 | 225 | 350 | 550 | 700 | 850 | |

| 5 | 300 | 500 | 750 | |||

| 6.1 | 400 | 650 | 1000 | |||

| 7 | 450 | 700 | 1100 | |||

| 8 | 500 | 750 | 1200 | |||

| 10 | 650 | 1000 | 1500 | |||

| Diameter | Length (inch) | Recommended Watts (W) | ||||

| 1/2" (-.02/.08mm) |

1.5 | 100 | 175 | 225 | ||

| 2.0 | 100 | 150 | 250 | 350 | 400 | |

| 2.5 | 200 | 350 | 500 | 650 | 800 | |

| 3.25 | 200 | 350 | 500 | 650 | 800 | |

| 4 | 250 | 400 | 650 | 800 | ||

| 5 | 400 | 650 | 1000 | 1250 | ||

| 6 | 500 | 800 | 1250 | |||

| 7 | 550 | 900 | 1250 | |||

| 8 | 800 | 1000 | 1500 | |||

| 10 | 1000 | 1500 | 1800 | |||

| 12 | 1000 | 1750 | 2000 | |||

| Diameter | Length (inch) | Recommended Watts (W) | ||||

| 5/8" (-.02/.08mm) |

1.5 | 150 | 175 | 275 | 350 | |

| 2 | 150 | 200 | 350 | 400 | 500 | |

| 2.5 | 200 | 300 | 450 | 550 | 650 | |

| 3.25 | 300 | 400 | 650 | 800 | 1000 | |

| 4 | 315 | 400 | 630 | 800 | 1000 | |

| 5 | 500 | 700 | 1100 | 1400 | 1800 | |

| 6 | 600 | 900 | 1600 | 1800 | ||

| 7 | 750 | 1000 | 1750 | |||

| 8 | 800 | 1250 | 2000 | |||

| 10 | 1000 | 1500 | 2500 | |||

| 12 | 1250 | 1800 | ||||

| 14 | 1500 | 2500 | ||||

| 16 | 1600 | 2000 | ||||

| Diameter | Length (inch) | Recommended Watts (W) | ||||

| 3/4" (-.02/.08mm) |

3 | 350 | 500 | 800 | 1000 | 1250 |

| 4 | 450 | 650 | 1000 | 1400 | 1600 | |

| 5 | 650 | 900 | 1400 | 1800 | 2200 | |

| 6 | 800 | 1100 | 1800 | 2200 | ||

| 7 | 900 | 1200 | 2000 | |||

| 8 | 1000 | 1500 | 2000 | |||

| 10 | 1600 | 2000 | ||||

| 12 | 1600 | 2000 | ||||

| 14 | 1750 | 2500 | ||||

| 16 | 2000 | 3000 | ||||

| 18 | 2500 | 3500 | ||||

| 20 | 2500 | 3500 | ||||

* More size is available on request.

| Wattage | ± 10 % |

| Max. Sheath Temperature | 750 ° C / 1380 ° F |

| Insulation Resistance | ≥ 5 MΏ at 500V (DC) |

| Length Tolerance | ± 1.5 % , min ± 1 mm |

| Diameter Range | 3 mm to 25.4 mm |

| Diameter Tolerance | -0.02 to -0.06, if not specified |

| Max. Voltage | 480 V |

| High Voltage Test | 1500 V |

| Max. Surface Load | 25 W/sq. cm or 150 W/sq. inch |

| Thermocouple | Type J / K |